15M 20M 25M 30M 35M stadium Automatic Lift High Mast Light Pole

Products Description

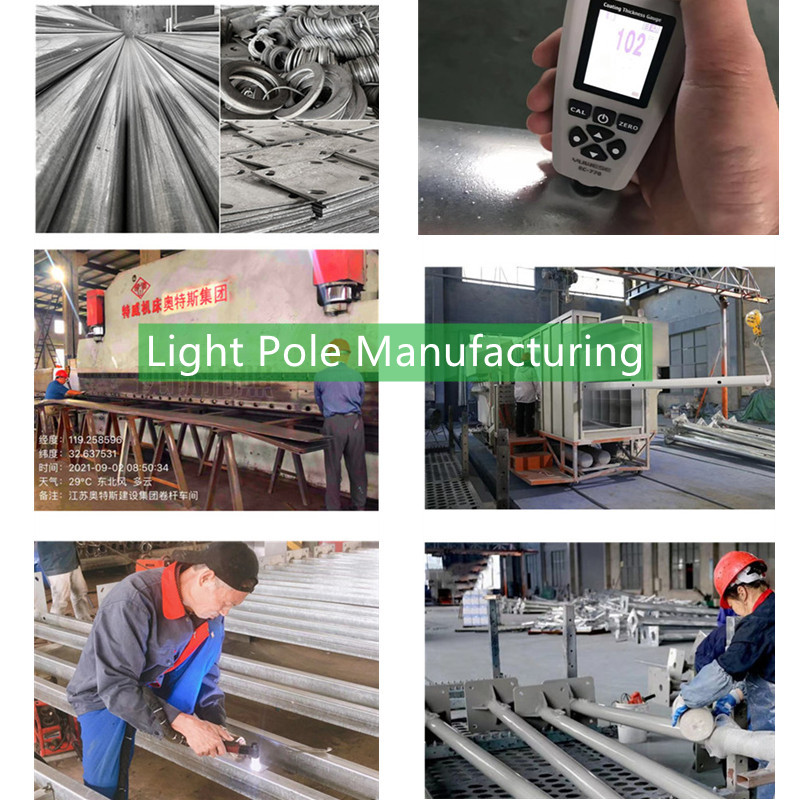

★Material: High quality international standard steel Q235B/Q345B

★Laser cutting:Narrow slit, high precision,smooth cutting surface,high energy density,short action time,small thermal affected area

★Welding: Robot automatic weld internal and external double welding makes pole more smooth

★Galvanized:The surface treatment technique of plating a layer of zinc on the surface of metals, alloys or other materials.

★Power Coating: Advanced technology,energy-saving and safe and reliable, and bright color.

★Packing: Bubble bag packaging mode, transport by special vehicle.

Company Profile

Autex is a professional enterprise engaged in manufacturing solar energy equipment and solar LED street lighting for over 15 years, Autex is now one of the important suppliers in this industry. We have a comprehensive range of solar panel, battery ,led light and light pole product lines, and various accessories. Our products are committed to rapid delivery and installation, with intelligent transportation and solar energy project products as outstanding work. Currently, Autex has become a large enterprise, Integrating product design, production, sales, and service. The factory covers an area of over 20000 square meters and has an annual output of over 100000 sets of lamp poles, Intelligence, green and energy-saving are the direction of our work, providing professional and timely services to all customers.

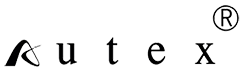

Pole Shapes

Products Paramenters

| Recommended Configurations | |

| Height of pole | From 15m to 40m |

| Shape of poles | Octagonal tapered;Straight square; Tubular stepped;Round conical;Polygon shaped;The shaft is folded into the desired shape using steel plates and longitudinally welded using an automatic welding machine |

| Material | Q235,Q345 steel,or equivalent |

| Arm/brackets | Single or double brackets/ arms;the shape and dimension as per customers requirement |

| Thickness | 1.8mm-20mm |

| Welding | Internal and external double welding makes the welding beautiful in shape.And confirms with international welding standard of CWB,BS EN15614,Flaw testing has been past. |

| Base plate mounted | Base plate is square or round in shape with slotted holes for anchor bolt,dimension as per customers requirement. |

| surface treatment | Hot dip galvanization with thickness of 80-100µm average in accordance with Chinese standard GB/T 13912-2002 or American standard |

| Wind resistance | According to customer's environment;Customized |

| Powder coating | Pure polyester powder painting, color is optional according to RAL Color stardand. |

| customized service | By communicating and offered |

Factory Manufacturing

Packing&Shipping

Installation Process

FAQ

Q1: Are you a manufacturer or a trade company?

A1: We are a manufacturer , we have our own factory , we can guarantee the delivery and quality of our products.

Q2. Can I have a sample order for led light?

A2: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q3. What about the lead time?

A3: Samples within 3 days, big order within 30 days.

Q4. Do you have any MOQ limit for led light order?

A4: Low MOQ, 1pc for sample checking is available.

Q5. How do you ship the goods and how long does it take to arrive?

A5: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

Q6. What about Payment?

A6:Bank Transfer (TT), Paypal,Western Union,Trade assurance;

30% the amount should be paid before producing,the balance 70% of the payment should be paid before shipping.

Q7. Is it OK to print my logo on led light product?

A7: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q8: How to deal with the faulty?

A8: Firstly, Our products are produced in strict quality control system and the defective rate will be less than 0.1%. Secondly,during the warranty period, we will repair or replace defected products.

Related Products

-

Phone

-

E-mail

-

WeChat

Judy

-

Top