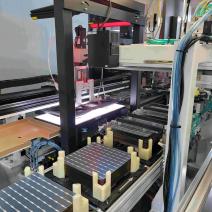

The development of solar panels cannot be separated from the continuous progress of technology. With the advancement of technology, the conversion efficiency of solar panels continues to improve. In the past, the conversion efficiency of solar panels was always low, but now, efficient solar panels can achieve a conversion efficiency of over 20%. In the future, technological progress will continue to promote the improvement of solar panel conversion efficiency, enabling it to more effectively convert solar energy into electricity. How does the solar panel be made through auto-production line?

Step 1: Solar cell test: Classify battery cells by testing their output parameters (current and voltage)

Step 2: Solar cell welding:Assemble the battery cells and achieve series and parallel connection through a busbar,

ensuring that the voltage and power meet the requirements

Step 3: Laminated laying:From bottom to top: glass, EVA, battery, EVA, fiberglass, backplane

Step 4 : Middle-test: Includes appearance test, IV test, EL test

Step 5: Component lamination: Melt the EVA to bond the battery, glass, and backplane together

Step 6: Trimming: Cut off the burrs formed by outward extension and solidification

Step 7: Install aluminum frame

Step 8: Welding junction box:Weld a box at the lead on the back of the component

Step 9: EL test: Test its output characteristics to determine the quality level of the component

Step 10: Package

Post time: Nov-08-2023